Charlotte Douglas International Airport

Structural Assessment and Repair Design

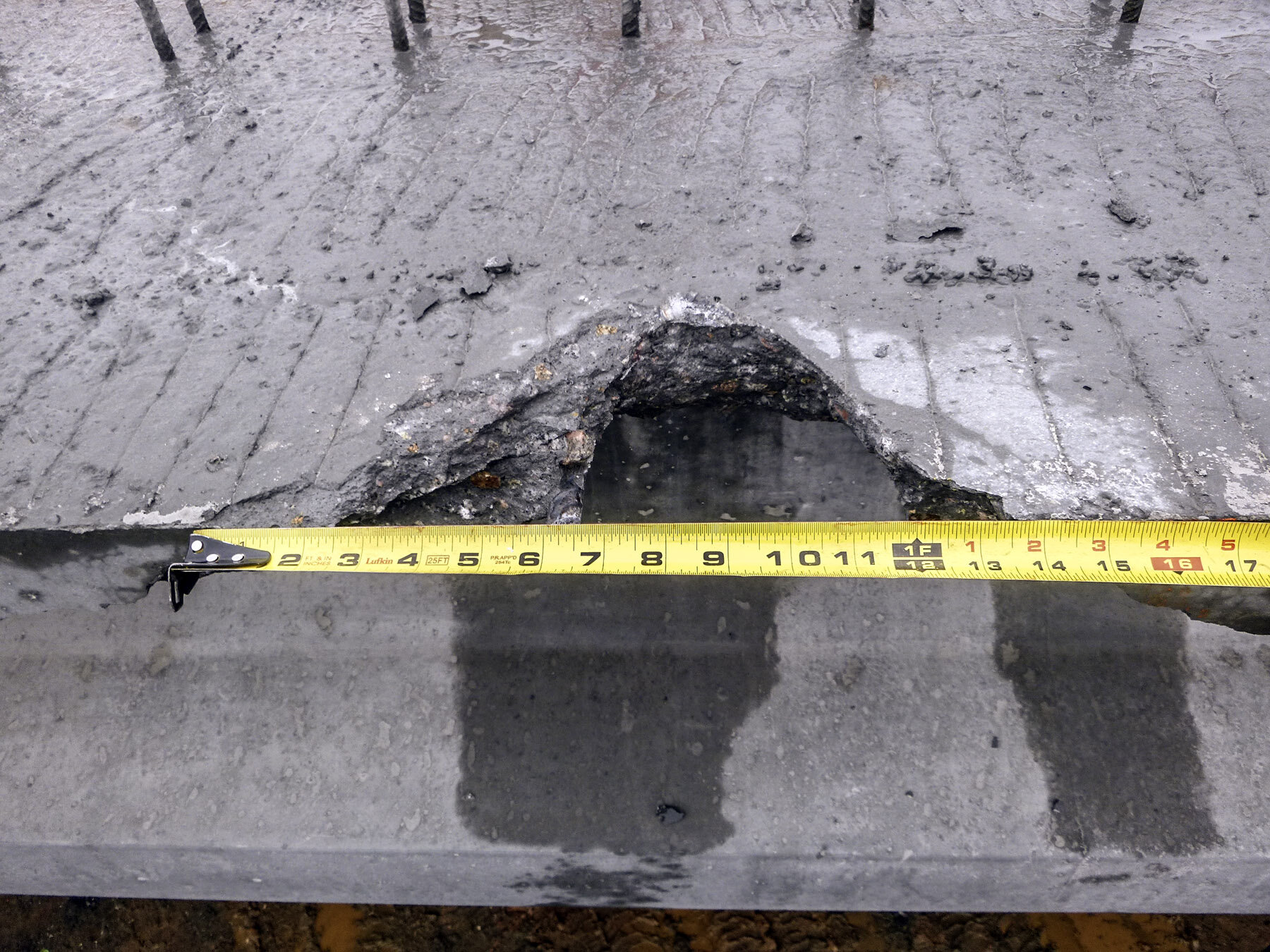

When one of their dump trucks accidentally hit a bridge at the Charlotte Douglas International Airport, Flatiron Construction Company called upon the structural engineering services of Alpha & Omega Group. On very short notice, A&O met Flatiron on site and provided a hands-on structural condition assessment to determine the severity of the damage. We documented the size and location of the impact on the girder and determined that no prestressing strands were impacted and there was minimal damage to the concrete bottom flange. Our investigation determined that the bridge girder did not suffer any loss in carrying capacity.

After this initial project with Flatiron, we assisted with several other projects at the airport. We designed the structural reinforcing for six trench drains for Concourse A West Ramp, Phase 2, also for Flatiron. A&O developed a plan and profile drawing for the six trench drains including a typical section, doweling into adjacent concrete slabs, bill of materials, and details needed to construct the trench drains. A&O coordinated with the designer and the geotechnical engineer to determine the appropriate design loads and soil properties for the design of the trench drains.

A&O assisted another contractor, Dakota Construction, in designing structural reinforcing for two trench drains for Concourse A Renovation Plans (prepared by C Design and Talbert, Bright, & Ellington). A&O developed a plan and profile drawing for the two trench drains, including a typical section, bill of materials and details needed to construct the trench drains. A&O coordinated with the designer and the geotechnical engineer to determine the appropriate design loads and soil properties for the design of the trench drains.

A&O assisted Flatiron again during construction of the elevated roadway for Arrivals and Departures. We helped determine whether the crane loads from the crane’s outriggers would be acceptable during construction and if there were any restrictions with the placement of the outriggers and the maximum load that could be lifted by the crane. A&O performed a detailed analysis of the elevated girders, bent caps, and columns to determine the limits for placement of the crane that would not cause excessive stress on any structural elements. The analysis enabled Flatiron to plan their work in an expedient manner and keep their construction on schedule.

During the construction of the elevated roadway project, Flatiron encountered several drilled shafts that were out of tolerance. A&O analyzed the drilled shafts to determine if the shafts and footings were acceptable “as is” or if remedial work was necessary. Several of the footings needed to be modified to redistribute the eccentric loading, requiring larger footings and additional reinforcement to transfer loads from the drilled shafts to the footings and columns supporting the elevated roadway. Ω

Overhead

- Client/owner:

Charlotte Douglas International Airport - Location:

Charlotte, NC - Service provided:

Structural engineering, analysis, and design - Contact:

Corey Morgan

Heavy Civil Divison

704-962-8969

Mike Starkey

Dakota Contracting Company

704-588-5567 - Start / completion:

3/2017 – 8/2019 - Project manager:

Ted Bartelt, PE

Experience

- Bridge design

- Bridge replacement

- Coordination

- Load Rating

- Construction plans and specifications

- Construction observation